Collaborative Robot

Introduction

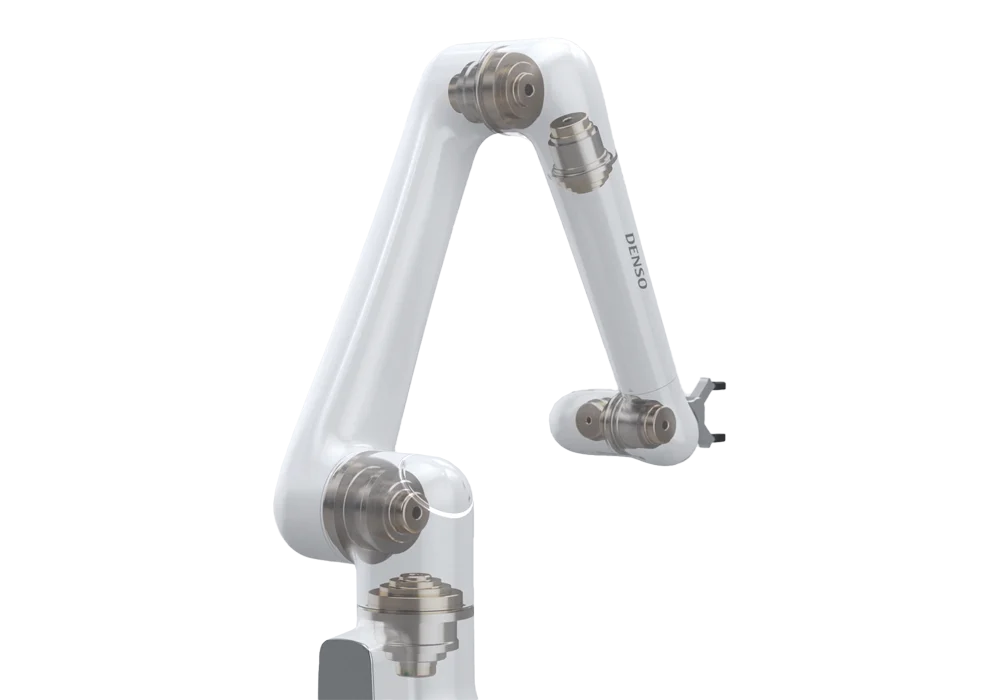

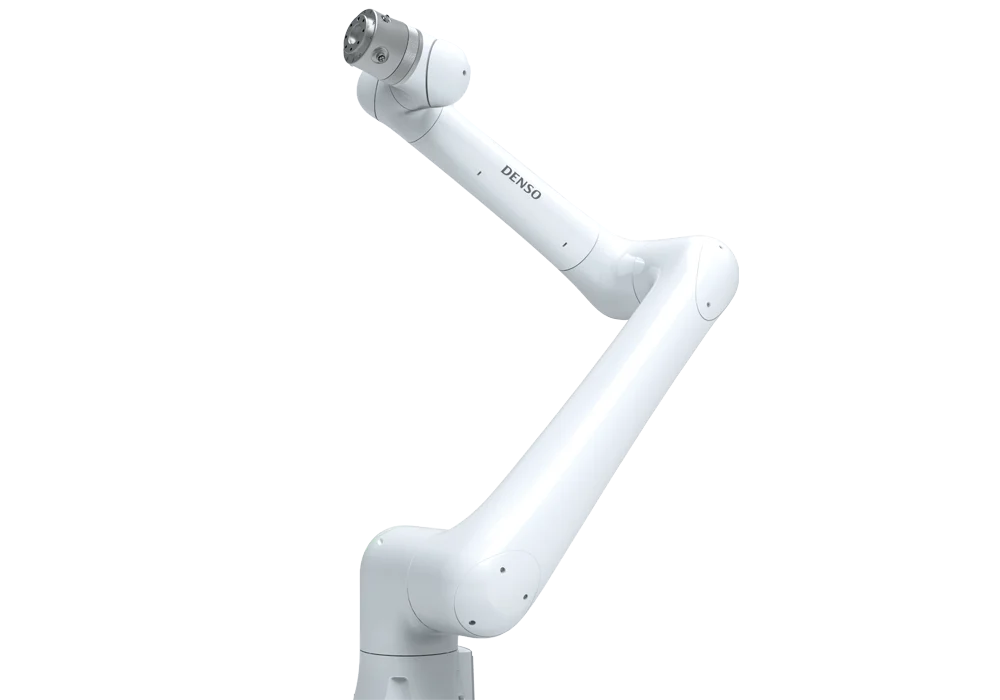

DENSO COBOTTA PRO Collaborative Robot

COBOTTA PRO is designed not merely for human–robot collaboration, but to continuously enhance productivity through collaboration.

In addition to performing simple tasks, it is well suited for real production processes such as assembly and inspection, delivering both high productivity and safety.

- Advanced High-Speed Performance

With a maximum TCP speed of 2,500 mm/s, COBOTTA PRO represents the top tier of collaborative robots. Its operating speed during high-speed motion surpasses that of many articulated robots. Each joint of the compact and lightweight robot arm is equipped with independently developed high-rigidity torque sensors, enabling higher acceleration. Cable routing and piping are integrated to the front end of the robot, providing enhanced versatility for a wide range of applications.

- Safety That Continuously Enhances Productivity

The development of COBOTTA PRO focuses on maintaining high safety standards while enabling high-speed operation, further improving productivity. In addition to its core functions, the robot arm incorporates newly developed “application-specific functions.” Furthermore, by leveraging optional components designed to enhance safety, COBOTTA PRO increases operating speed during collaborative tasks, resulting in higher overall productivity.

- Simple and Easy Teaching

Direct teaching enables intuitive instruction in a short time, fully leveraging its strengths. In addition to basic functions, COBOTTA PRO features a newly developed, easy-to-use dedicated teaching system. By utilizing its extensive functions, users can perform fine adjustments that are difficult to achieve with conventional direct teaching. The teaching system allows precise instruction to be completed quickly, while the user-friendly programming system enables even first-time robot users to automate not only simple tasks but also moderately complex processes. Together, these systems simplify automation.

- Integrated Control for Automating Advanced Tasks

COBOTTA PRO adopts the robot controller RC9 as its foundation and utilizes CRC9, enabling comprehensive equipment integration and control, as well as an open development environment—similar to RC9. In addition, when combined with our 3D vision system and general-purpose AI software, COBOTTA PRO enables the automation of advanced tasks that previously required highly skilled manual labor.

Product Specifications:

| Item / Model | COBOTTA PRO 900 | COBOTTA PRO 1300 |

|---|---|---|

| Axes | 6 axes | 6 axes |

| Reducer | Harmonic reducers on all axes | Harmonic reducers on all axes |

| Arm Length (1st + 2nd Arm) | 908 mm | 1304 mm |

| Rated Payload | 6 kg | 12 kg |

| Max. Allowable Moment | Axis 4: 0.8 kg·m² Axis 5: 0.45 kg·m² Axis 6: 0.1 kg·m² | Axis 4: 1.45 kg·m² Axis 5: 0.9 kg·m² Axis 6: 0.35 kg·m² |

| Position Repeatability | ±0.03 mm | ±0.04mm |

| Protection Rating | IP54 (dust- and splash-proof) | IP54 (dust- and splash-proof) |

| Cleanliness (ISO 14644-1) | Class 5 (cleanroom type) | Class 5 (cleanroom type) |

| Operating Environment | Ambient temperature: 0–50 °C Relative humidity: 20–90% (non-condensing) Vibration: ≤ 4.9 m/s² (0.5 G) | Ambient temperature: 0–50 °C Relative humidity: 20–90% (non-condensing) Vibration: ≤ 4.9 m/s² (0.5 G) |

| Robot Weight | Approx. 29 kg | Approx. 41 kg |

| Safety Standards | ISO 10218-1:2011, ISO 13849-1:2015, ISO/TS 15066:2016, IEC 60204-1:2016/A1:2021 EN 61000-6-2:2005, EN 61000-6-4:2007/A1:2011 EN 61000-6-7:2015 | ISO 10218-1:2011, ISO 13849-1:2015, ISO/TS 15066:2016, IEC 60204-1:2016/A1:2021 EN 61000-6-2:2005, EN 61000-6-4:2007/A1:2011 EN 61000-6-7:2015 |

| Noise Level | ≤ 65 dB | ≤ 65 dB |

| Pollution Degree (IEC 60664-1) | 3 | 3 |

| Max. Speed in Collaborative Mode | 1,800 mm/s (without contact sensing skin) 2,000 mm/s (with contact sensing skin) | 1,800 mm/s (without contact sensing skin) 2,000 mm/s (with contact sensing skin) |

| Max. TCP Linear Speed (Non-Collaborative Mode) | 2,100mm/s | 2,500mm/s |

Download