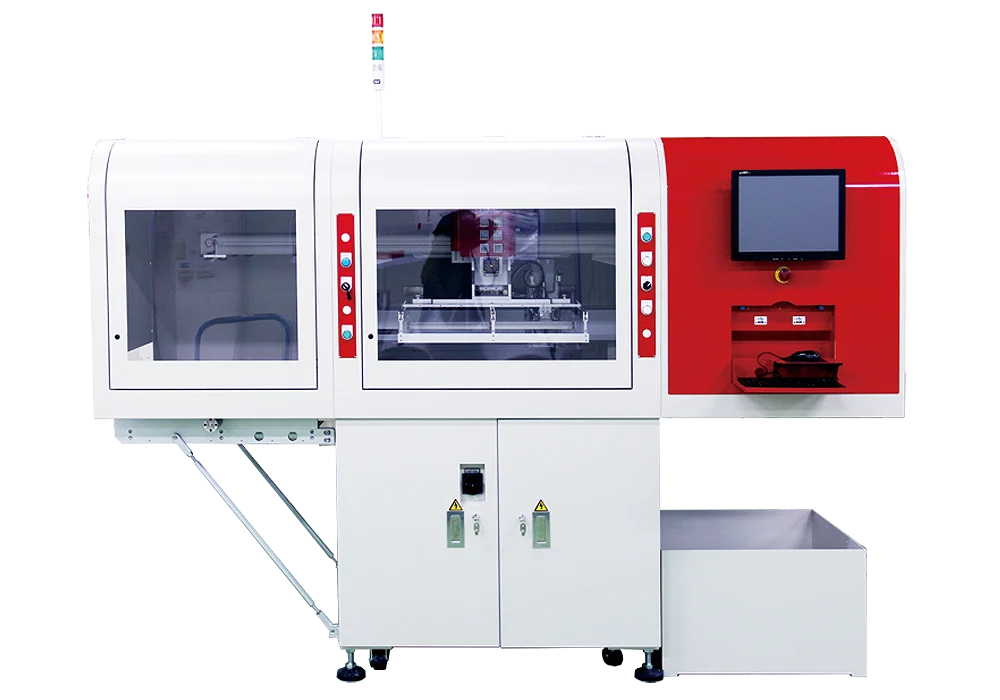

Fully-automatic PCB Separator

Fully-automatic PCB Separator

Building on the excellent design of the AUO series, the large-sized work platform, combined with the fully automated in/out material handling system, has given birth to the fully automated inline AUI cutting machine.

The AUI series is characterized by cleanliness, precision, speed, and ease of operation. The entire series is also suitable for a wide range of small to large PCB panels.

Additionally, to meet different production needs, Aurotek offers more flexible PCB milling solutions, such as spindles, dust removal systems, and other high-end optional features, allowing you to tailor the solution to your needs and achieve higher cost efficiency.

The AUI series closely aligns with your production management requirements, offering an easy-to-use interface, cutting path simulation and optimization, and foolproof operational processes. It combines production management capabilities, user-friendliness, safety, and traceability of production data in one machine.

Product Features:

- Efficient

- High-Performance Industrial Dust Collector

- Small dust-collecting duct designed for upward or downward dust extraction systems

- Duct is close to the milling area, removing dust at once while depaneling

- Accurate

- KURODA high precision ball screw

- Panasonic servo motor

- SycoTec spindle

- Advantech industrial computer

- Aurotek motion control card

- Aurotek Vision System

- Core Performance Features

- We gurantee: Cpk>=1.33

- Positioning Repeatability ±10 μm

- Cutting Accuracy ±80 μm

- Speedy

- High-speed axis modules reaches up to ( max. ) 1200mm/sec.

- Maximum cutting speed 100mm/sec.

- Customized fixture and tools. Production changeover can be done in just a few seconds.

- Yield Increasing – Easy to use is a MUST. We design machines for:

- Manageability

- Usability

- Safety

- Traceability

Product Specifications:

| Model | AUI 5000 / AUI 5000C | AUI 6000 |

|---|---|---|

| Working Area | X: 630mm, Y: 350mm | X: 850mm, Y: 560mm |

| Working Table | 1 | 1 |

| PCB Thickness | 0.8~3.0mm | 0.8~3.0mm |

| PCB Component Height (Max.) | Top: 15mm / Down: 35mm | Top: 15mm / Down: 35mm |

| Motion Control | 6 Axes | 6 Axes |

| Moving Speed | Standard: X, Y=1,000 mm/s; Z=750 mm/s; Carrier X=700 mm/s; Carrier Z=750 mm/s Maximum: X, Y=1, 200 mm/s; Z=750 mm/s; Carrier X=700 mm/s; Carrier Z=750 mm/s | Standard: X, Y=1,000 mm/s; Z=750 mm/s; Carrier X=700 mm/s; Carrier Z=750 mm/s Maximum: X, Y=1, 200 mm/s; Z=750 mm/s; Carrier X=700 mm/s; Carrier Z=750 mm/s |

| Cutting Speed | 0~100 mm/s | 0~100 mm/s |

| Cutting Accuracy | ±80 μm | ±80 μm |

| Positioning Repeatability | ±10 μm | ±10 μm |

| Cutting Modes | Linear, L-Curve, U-Curve, Arc, Circular | Linear, L-Curve, U-Curve, Arc, Circular |

| Standard Bits | Ø 1.0 mm, Ø 1.2 mm, Ø 1.6 mm, Ø 2.0 mm | Ø 1.0 mm, Ø 1.2 mm, Ø 1.6 mm, Ø 2.0 mm |

| Operating System | Windows 10 | Windows 10 |

| Pneumatic Pressure | ≧0.65 Mpa (≧6.5 Bar) | ≧0.65 Mpa (≧6.5 Bar) |

| Working Height | 890 ~ 940 mm | 890 ~ 940 mm |

| Dimensions (W*D*H) | 2572 x 1583 x 1720 mm + Signal Light 561 mm | 3222 x 1577 x 1696 mm + Signal Light 561 mm |

| Net Weight (Approx.) | 860 kg | 1,050 kg |

| Vacuum Cleaner | Bottom suction with air volume-type dust collection system | Bottom suction with air volume-type dust collection system |

| Standard Spindle | SycoTec High Speed Spindle | SycoTec High Speed Spindle |

| Standard Monitor | 22” Full HD Monitor | 22” Full HD Monitor |

| Power Supply | 3 Phase AC220 V±3% 50 Hz/60 Hz, 4.0 kW | 3 Phase AC220 V±3% 50 Hz/60 Hz, 4.0 kW |