Advantech|Delivery Robot Reduce Downtime and Boost Transport Efficiency by 75%

Client Company Overview

Advantech is a global leader in industrial computing, providing the industry’s most reliable and comprehensive embedded platforms and industrial automation solutions. Its core product offerings span industrial PCs, network communication systems, and automated system testing, covering a wide range of industrial automation applications. Advantech delivers complete IoT hardware and software solutions, achieving an impressive annual revenue of NT$64.5 billion.

Operational Pain Points

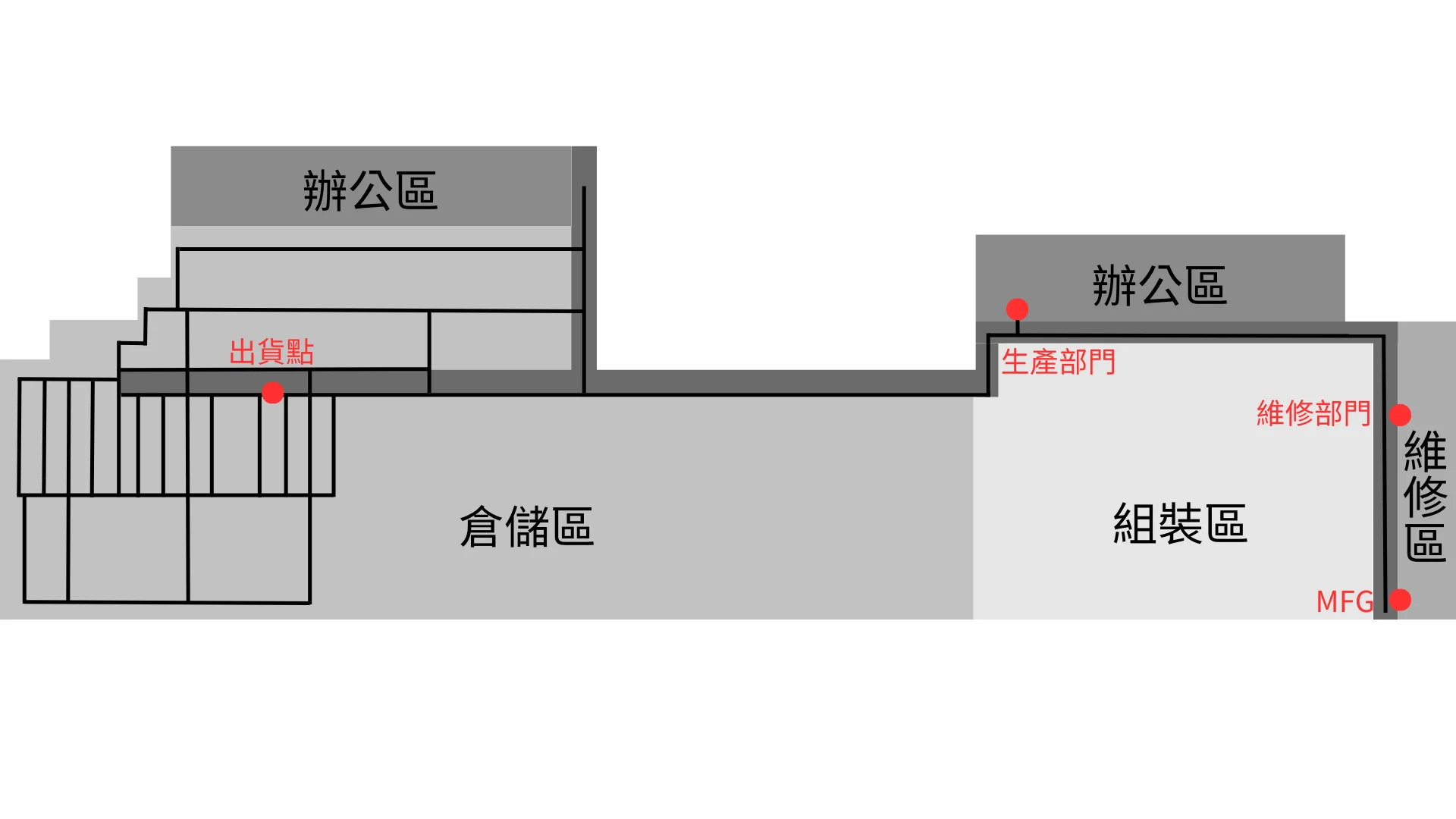

This project focused on Advantech’s computer assembly plant, where materials must be transported from the warehouse to the production line. Frequent deliveries require significant manual time and effort. Similar challenges are found across other assembly facilities:

1. Unpredictable material demand causing workflow interruptions:

During product inspection, missing or damaged components are often discovered. Operators typically wait until enough items accumulate before retrieving materials from the warehouse, resulting in downtime during the waiting period.

2. Time-consuming manual delivery:

The distance between multiple stations is roughly 900 meters, and staff travel back and forth up to 50 times per day. This equals at least 45 km of manual transportation daily, creating a substantial labor burden. The estimated time cost of manual delivery is calculated as follows:

260 meters × 50 trips = 13 km (round-trip transport distance × number of manual deliveries per day = total daily transport distance)

13 km ÷ 4.6 km/hr = 2.82 hours (total daily transport distance ÷ average human walking speed = total daily delivery time)

Taking these factors into consideration, the assembly plant adopted Aurotek’s PD50 Goods-to-Person Solution. This system not only replaces the time-consuming manual transport process but also allows employees to receive materials without leaving their workstation. As a result, workflow interruptions are reduced and overall operational efficiency is significantly improved.

Implementation of the Solution – Delivery Robot

- User-friendly PD50 interface: Employees can quickly adapt to the system with minimal training.

- Automatic obstacle avoidance: Ensures a safe human–robot collaborative environment.

- Open-shelf design: Materials are easy to see and retrieve; each shelf supports up to 10 kg, with a maximum transport capacity of 40 kg per trip.

- Smooth movement in narrow production areas: Provides a more efficient delivery experience and truly enables a goods-to-person workflow.

Results and Impact

For equipment operations, utilization rate (or equipment usage efficiency, in this case) is a key indicator of performance. By comparing metrics before and after process optimization, the analysis shows that after implementing the PD50 material handling robot, the system can achieve payback in as little as three months, with the ROI reaching up to 341%.

Conclusion

Aurotek’s PD50 enables point-to-point automated parts delivery, replacing frequent manual transport tasks while ensuring accurate and reliable material delivery to designated locations. This achieves a highly efficient goods-to-person workflow that minimizes workflow interruptions caused by staff movement and boosts overall production efficiency.

The PD50 demonstrates significant potential in modern manufacturing, offering companies a new solution to address labor shortages and productivity challenges.

Watch the customer interview video to learn more about the full solution!