Aurotek x MUJIN|Logistics Automation Pallet Exchange Solution

Mujin Robot Pallet Exchanger — Enabling Full Automation

Mujin Pallet Exchanger

Seamlessly performs both unloading and pallet stacking at the same time, enabling fully automated pallet-handling workflows.

The ideal solution for labor-intensive tasks and workforce shortages.

Eliminate Manual Workload — Achieve Fully Automated Pallet Exchange

Handling capacity of over 600 boxes per hour with a maximum payload of 25 kg

High Performance × Stable Handling

Processes over 600 boxes per hour and supports up to 25 kg per box, enabling continuous, stable, and highly efficient automated material handling.

Smart Stacking × Multi-Specification Compatibility

Simply input box dimensions and pallet size, and the system automatically generates the stacking mode. With real-time robotic trajectory planning, it efficiently completes stacking tasks across different pallet specifications.

No Fixed Equipment × AGV Integration

Through integrated control of the Mujin robot and AGVs, unmanned transport is achieved from storage to the work area, creating a flexible and scalable next-generation logistics system.

Pallet Exchanger — Single-Robot Solution

Allows pallet transfer using manual labor or forklifts, enabling fast deployment and excellent spatial flexibility.

Application Features

Suitable for environments without integrated automation systems

Pallets are moved in and out of the robot area by manual labor or forklifts. The structure is simple and requires no modification to existing workflows.

Deployment Advantages

No complex system integration required; the equipment design is clean and minimal

Can be deployed in a short time with low cost, enabling fast go-live even in confined spaces. Flexible to adapt to existing facility layouts and equipment conditions.

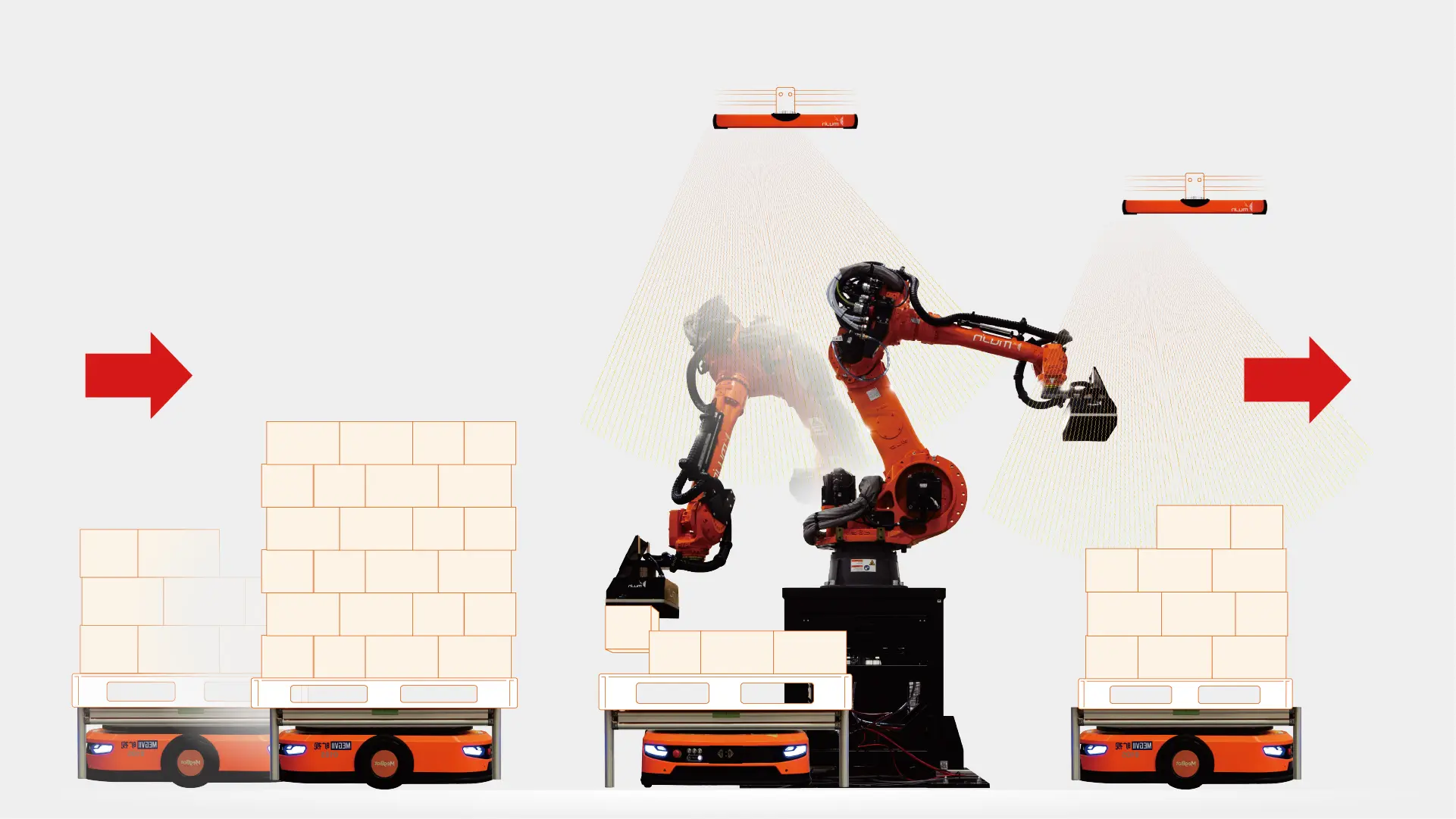

Pallet Exchanger — AGV Integrated Solution

Combining intelligent robots with AGVs to achieve a fully automated workflow

Application Features

With the rise of e-commerce and the trend toward multi-SKU, small-batch shipments, the market places strong emphasis on reduced manual handling and flexible automation. The AGV-integrated solution has already been widely adopted by many Japanese enterprises, with extensive real-world cases.

Deployment Advantages

AGVs automatically connect pallet exchange with storage-area transport, forming a seamless workflow.

No fixed conveyor equipment is required, enabling flexible deployment and high scalability. The system can integrate with upper-level software such as WMS, allowing rapid adjustments in response to changing operational processes.

Interested in learning more about automated sorting and smart logistics solutions?