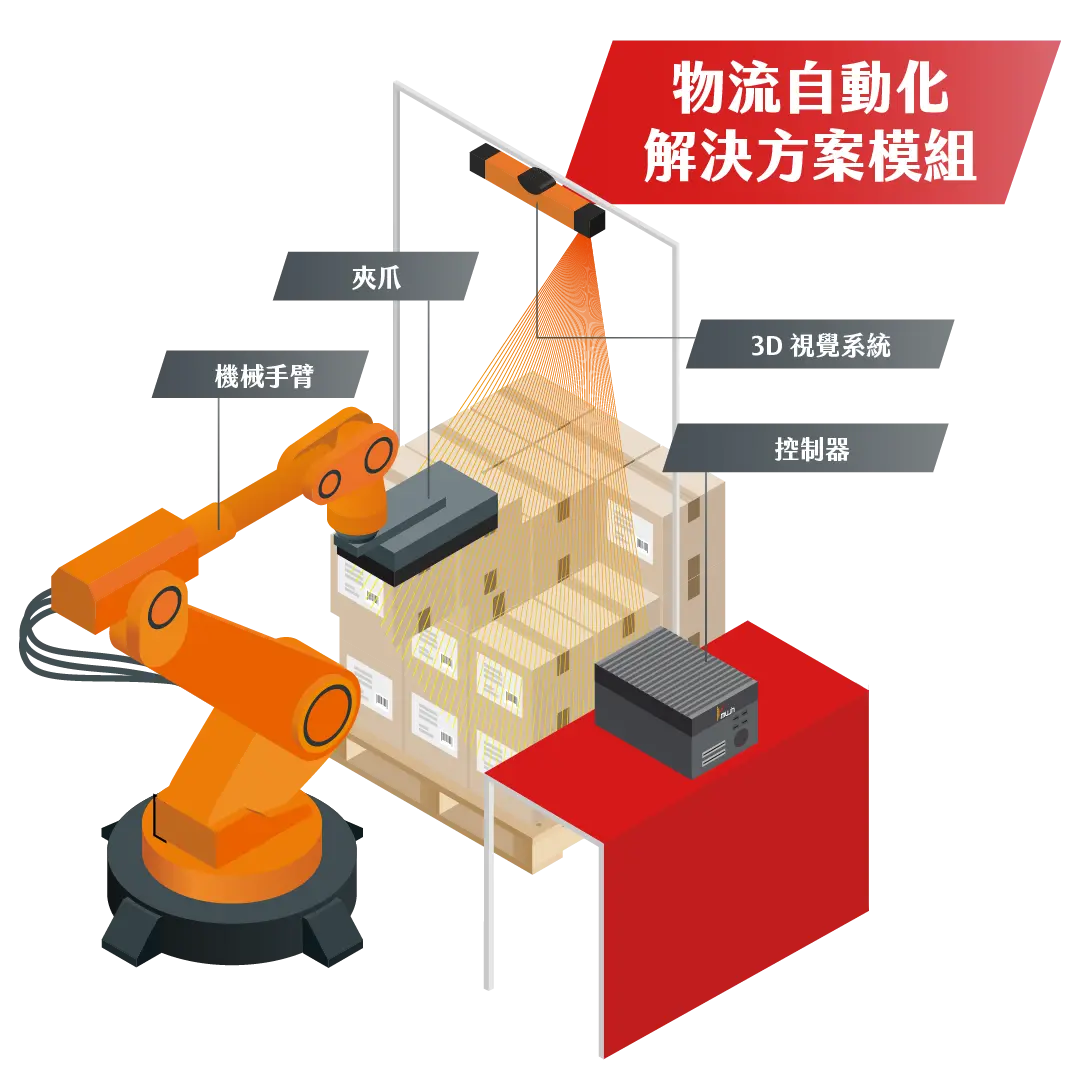

Aurotek x MUJIN|Logistics Automation Depalletizing Solution

Achieve fully automated unloading — powering a new era of efficiency for e-commerce and warehouse operations

Key Features of the Mujin Depalletizing Solution

In smart logistics, efficiency is driven not only by point-to-point transport but also by high-performance automated sorting — creating a safer, faster, and more intelligent logistics environment.

- Industry-leading speed: up to 1,100 boxes/hour

- Handles cartons, bags, and totes with ease

- Instant registration of new items — no teaching required

- Supports measurement data upload to upper-level systems

Single-Item Depalletizing Solution

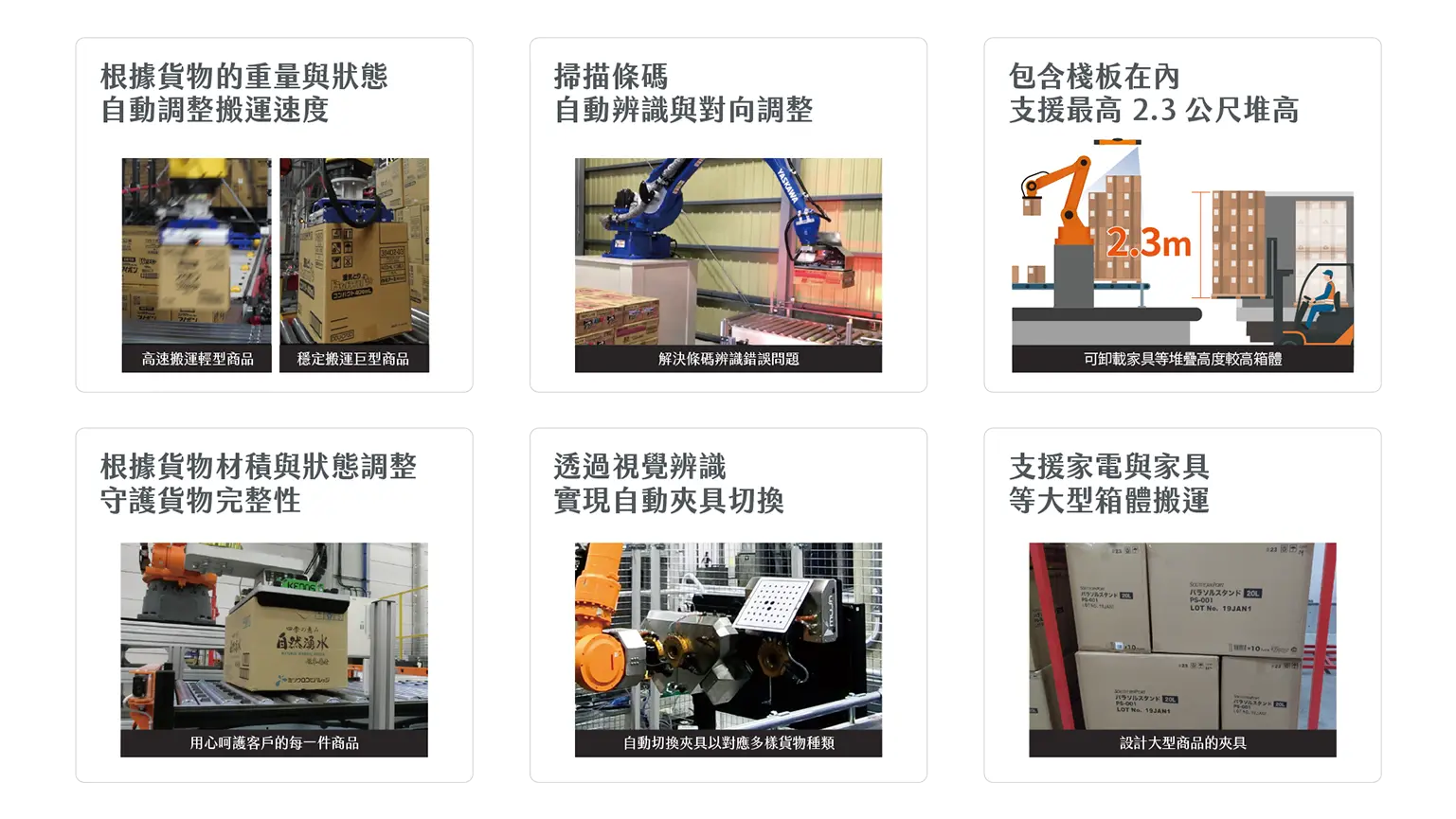

Using a standard single-pick gripper, the system achieves over 900 boxes per hour with high efficiency. With the Mujin intelligent multi-channel gripper—featuring independently controlled suction channels—it delivers an industry-leading throughput of over 1,100 boxes per hour. Combined with teachless technology, the system adapts to various stacking patterns and supports multiple optional configurations for highly flexible operation.

Mixed-Item Depalletizing Solution

Unknown items can be automatically identified, with size, pattern, weight, and position data recorded into the database to build Mujin’s proprietary teachless intelligent system. The fully automated workflow smoothly handles multi-SKU depalletizing tasks. Even in areas that are difficult to recognize, risk-prediction logic prevents mis-picks and significantly enhances safety.

Use Case — Mujin x Nichirei Logistics Group|Mixed-Item Depalletizing

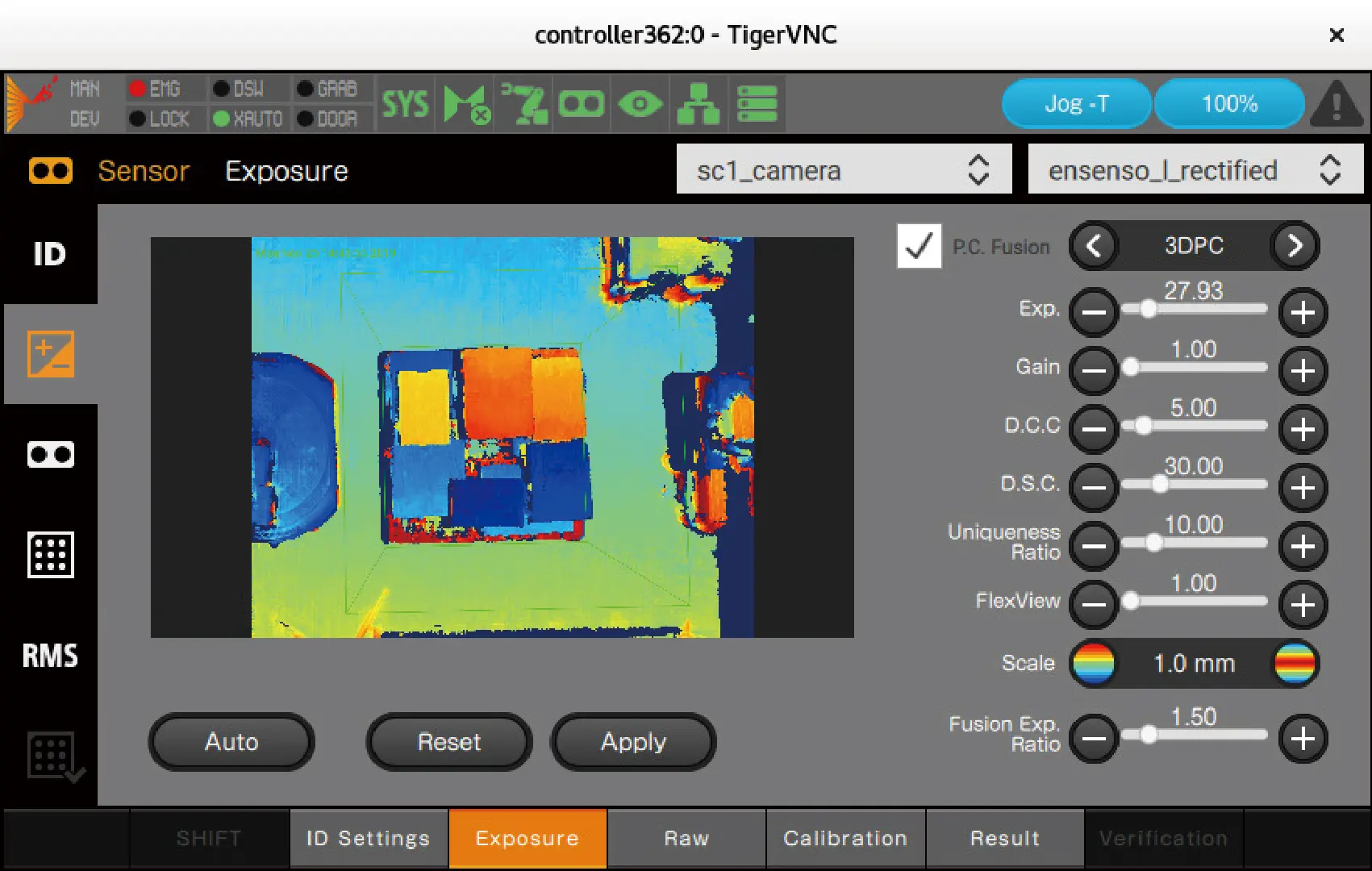

Mujin Vision 3D — Industry-Leading Detection Performance

IP65-rated protection with excellent dustproof and waterproof capability

Ultra-wide-area structured-light technology for larger scan coverage and faster recognition

Lightweight design reduces equipment cost and installation load

Equipped with the latest image sensor with 60% higher resolution

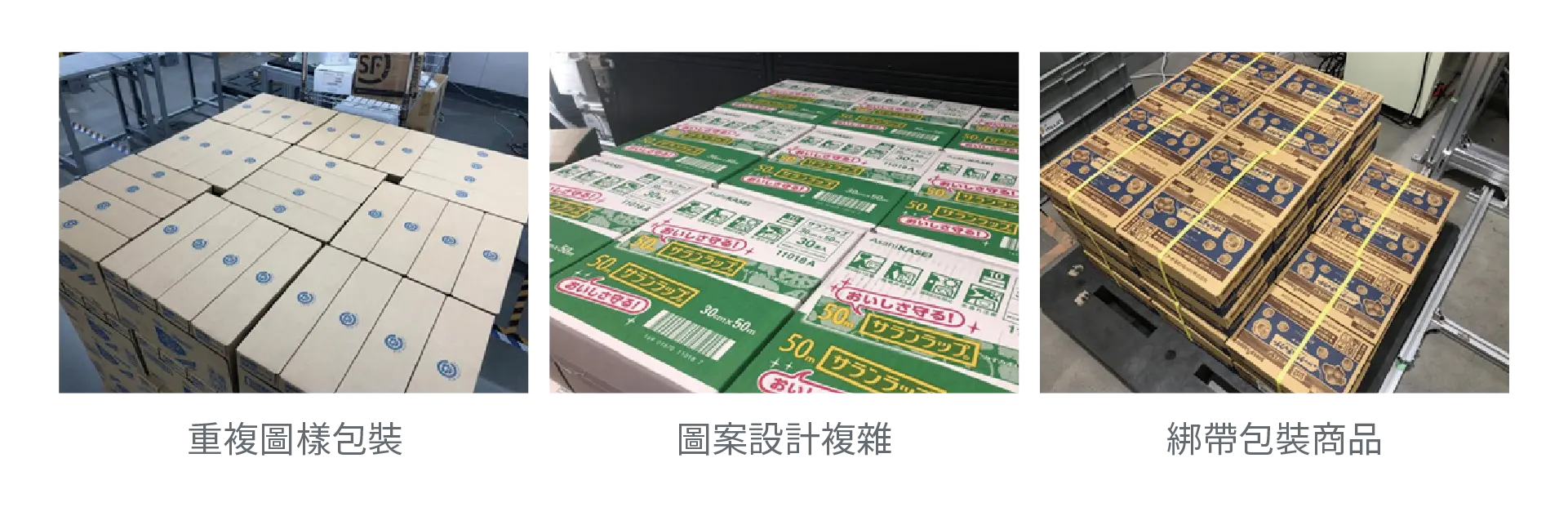

High-Precision Recognition for Challenging Packages

Accurately identifies difficult items that other systems often misdetect, ensuring stable and reliable operation.

Equipment Recognition to Prevent Collisions

Automatically detects equipment misalignment or position shifts to prevent collisions and operation errors. Supports carts, logistics trolleys, pallets, and various other equipment types.

Intuitive Interface — Simple and Easy to Use

Interested in learning more about automated sorting and smart logistics solutions?