【Metal Processing Plant】Zero-Blind-Spot Smart Cleaning — 30% Efficiency Boost

Client Company Overview

As the largest aluminum extrusion and metal processing plant in northern Taiwan, the company possesses a comprehensive aluminum extrusion machinery system and extensive experience in OEM integration for industrial equipment. Its core products include FOG lamination equipment, OCA bonding equipment, FOB lamination systems, and backlight module bonding machines, with annual revenue reaching up to NT$1.6 billion.

Common Cleaning Challenges in Metal Processing Facilities

In this project, Aurotek collaborated with the processing plant to deploy autonomous cleaning robots. Most CNC metalworking factories face multiple types of contamination—such as oil stains, metal chips, and dust. The most common challenges include:

1. Dust and oil contamination: Due to continuous machine-tool operation, large amounts of cutting fluid and metal debris accumulate.

2. Large facility area: The cleaning coverage area is extremely large—up to 1200 ping (approx. 39,600 sq ft)—because of the presence of large industrial machines.

3. Labor shortage: Hiring cleaning staff is difficult, and it is challenging to track cleaning performance consistently.

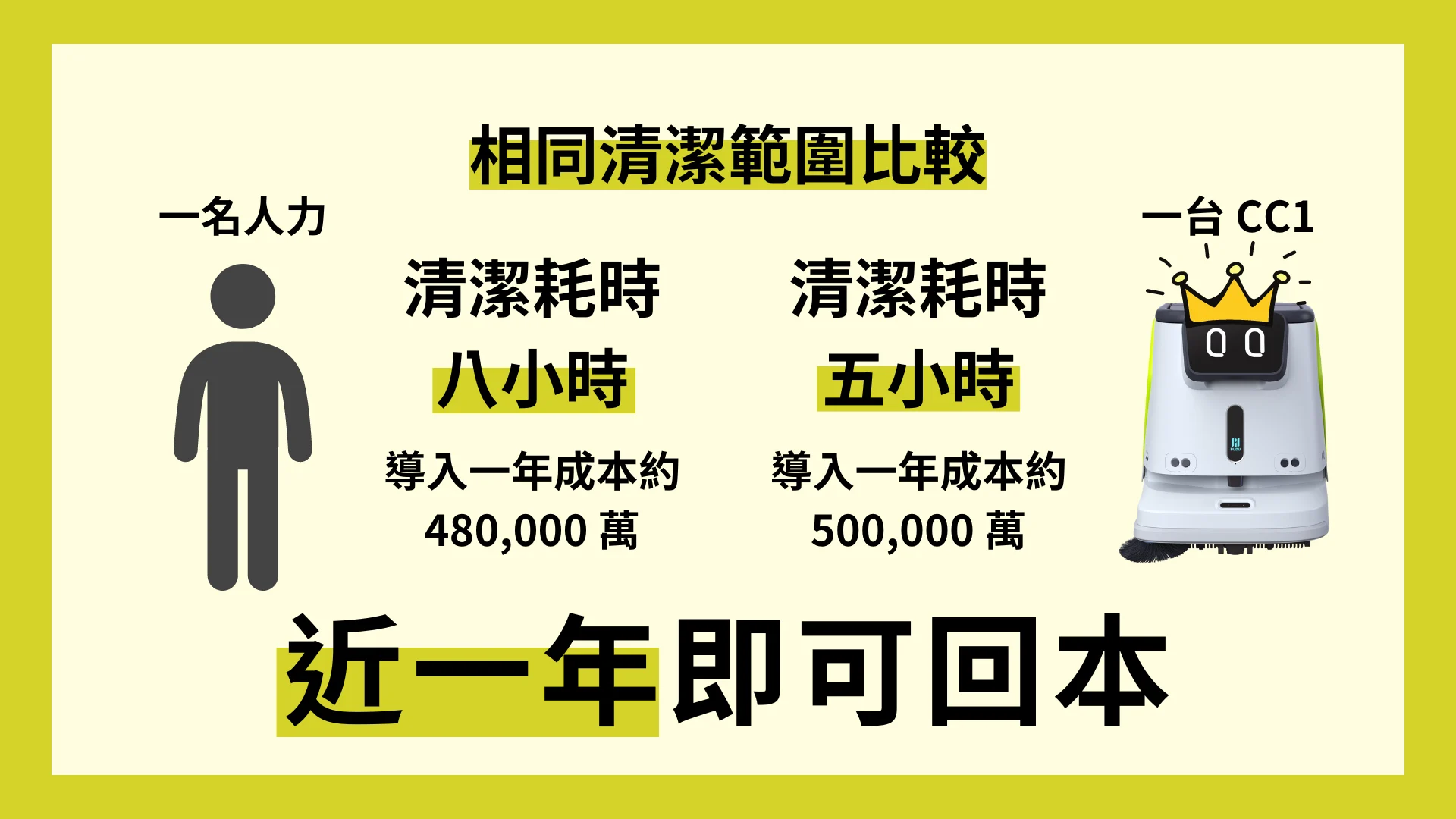

Given these harsh conditions, factories are actively seeking solutions that can adapt cleaning performance based on production demands. Aurotek recommended deploying the CC1 cleaning robot, equipped with four interchangeable modules—vacuuming, sweeping, scrubbing, and dust-mopping—allowing flexible configuration to achieve optimal cleaning results across different environments.

Implementation of the Solution

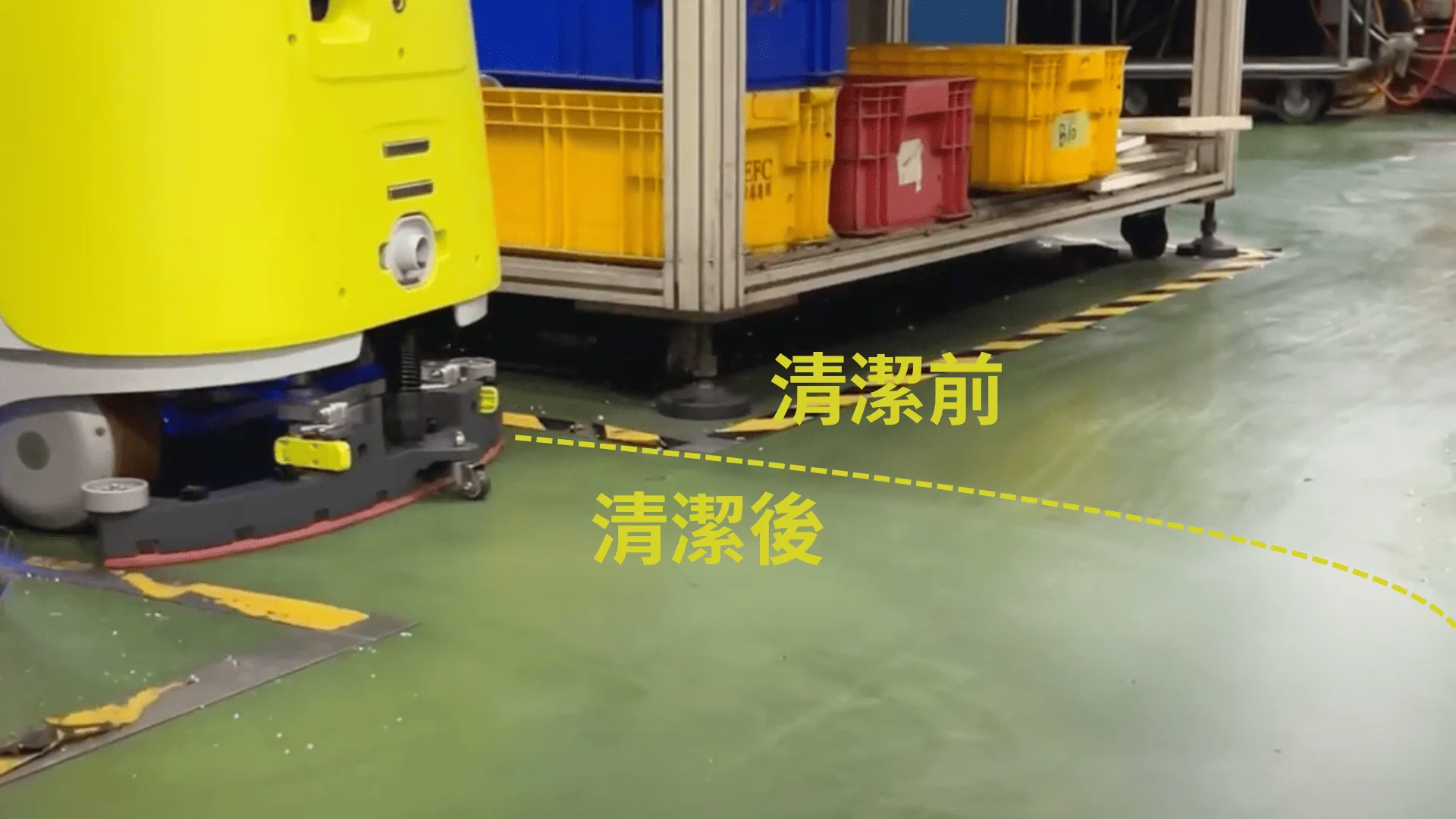

After adopting the smart cleaning solution, overall cleaning time was significantly reduced. Employees no longer needed to reserve shift-transition time for cleaning, allowing them to fully focus on production tasks. With the scheduling feature, the CC1 robot performs cleaning autonomously at designated times—completely without human intervention.

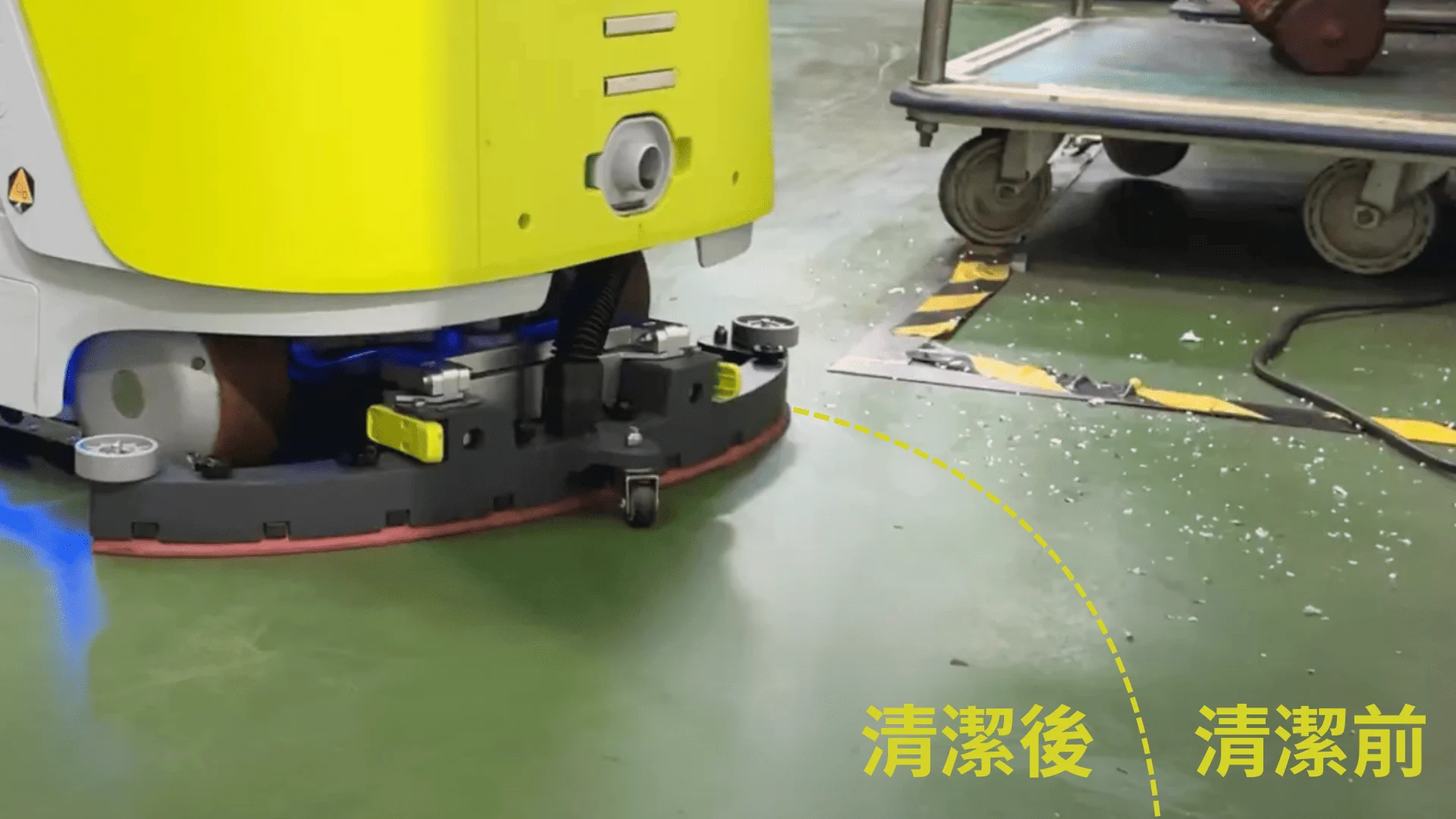

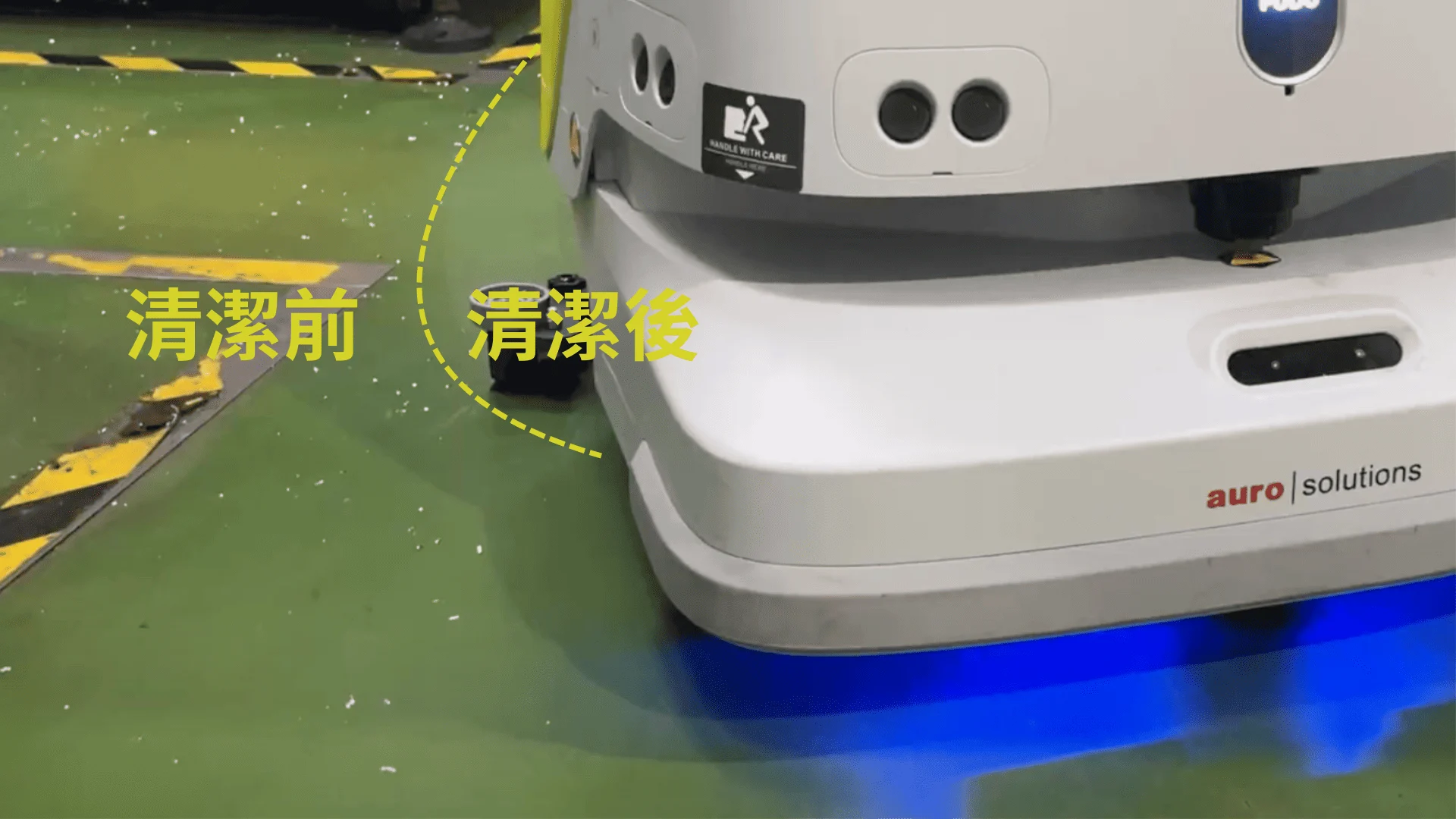

Once deployed, the CC1 robot successfully eliminated stubborn oil stains and metal debris on the floor. Each cleaning cycle now takes only 20 to 25 minutes to cover a large area.

Impact of Smart Cleaning

Severe oil contamination and dust are common conditions in most metal processing plants. These factors often create safety risks in the workplace and represent the most difficult and least desirable cleaning tasks. When such contamination accumulates over time, it significantly impacts worker efficiency and shortens machine lifespan.

By introducing cleaning robots into these 3K environments—kitanai (dirty), kitsui (difficult), and kiken (dangerous)—robots can replace humans in harsh working conditions. Unlike manual labor, robot operation is unaffected by fatigue or emotional fluctuations. They provide seamless, zero-blind-spot cleaning even in heavily polluted areas, while scheduled cleaning tasks keep the environment consistently clean and reduce safety hazards.