【See Box Corporation】 Cleaning Robot as Mobile Security — Improving Safety & Facility Cleanliness

Client Company Overview

See Box Corporation is the largest plastic food container manufacturer in Taiwan, specializing in the production of various beverage cups. With over 40 production lines, the company ships more than 1 billion cups annually and generates over NT$1.2 billion in revenue, solidifying its position as Taiwan’s leading plastic cup brand. In recent years, See Box Corporation has introduced 3D color-printing prototyping technology and successfully developed biodegradable plastic materials, bringing new momentum to the beverage cup market.

Cleaning Challenges in the Plastics Manufacturing Industry

In the plastics processing industry, the production flow from raw materials to finished products is inherently complex. To stay competitive in a market characterized by high customization, small-batch diversification, and constant variability, factories often operate with extensive production lines and large-scale capacity. These environments are vast and complex, leading to several common cleaning challenges:

- Plastic dust dispersion: Large volumes of plastic particles are generated during production, accumulating in corners and hard-to-reach areas.

- Open-area cleaning demands: Shipping docks easily collect dust, and pallet jacks leave wheel marks, increasing manual cleaning difficulty.

- Numerous production lines: A high number of lines operating across multiple floors makes facility cleaning more complicated.

- Labor shortages: Cleaning work is physically demanding, leading to unstable manpower availability and inconsistent cleaning quality.

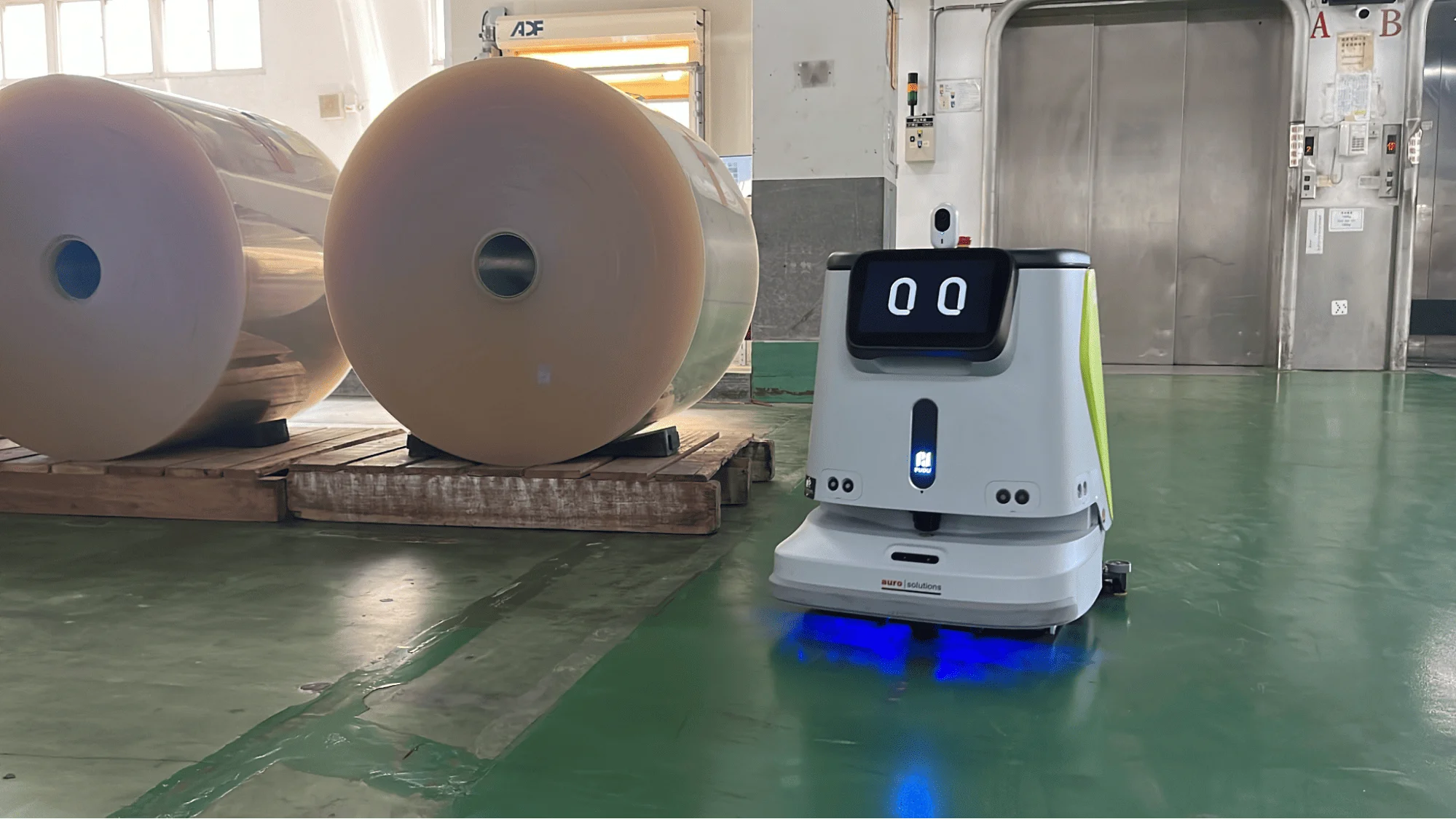

Aurotek’s CC1 Industrial/Commercial Cleaning Robot effectively addresses these challenges. With edge-cleaning capabilities and adaptive navigation, CC1 ensures thorough, zero-blind-spot cleaning even in complex environments. It removes fine dust and particles efficiently and can clean up to 8,250 m² per day—working on schedule, without interruption—greatly improving workplace cleanliness and overall environment quality.

Implementation of the Solution – CC1 Industrial Cleaning Robot

Outstanding Floor-Cleaning Performance Elevates Workplace Hygiene — Allowing Staff to Focus on Core Operations

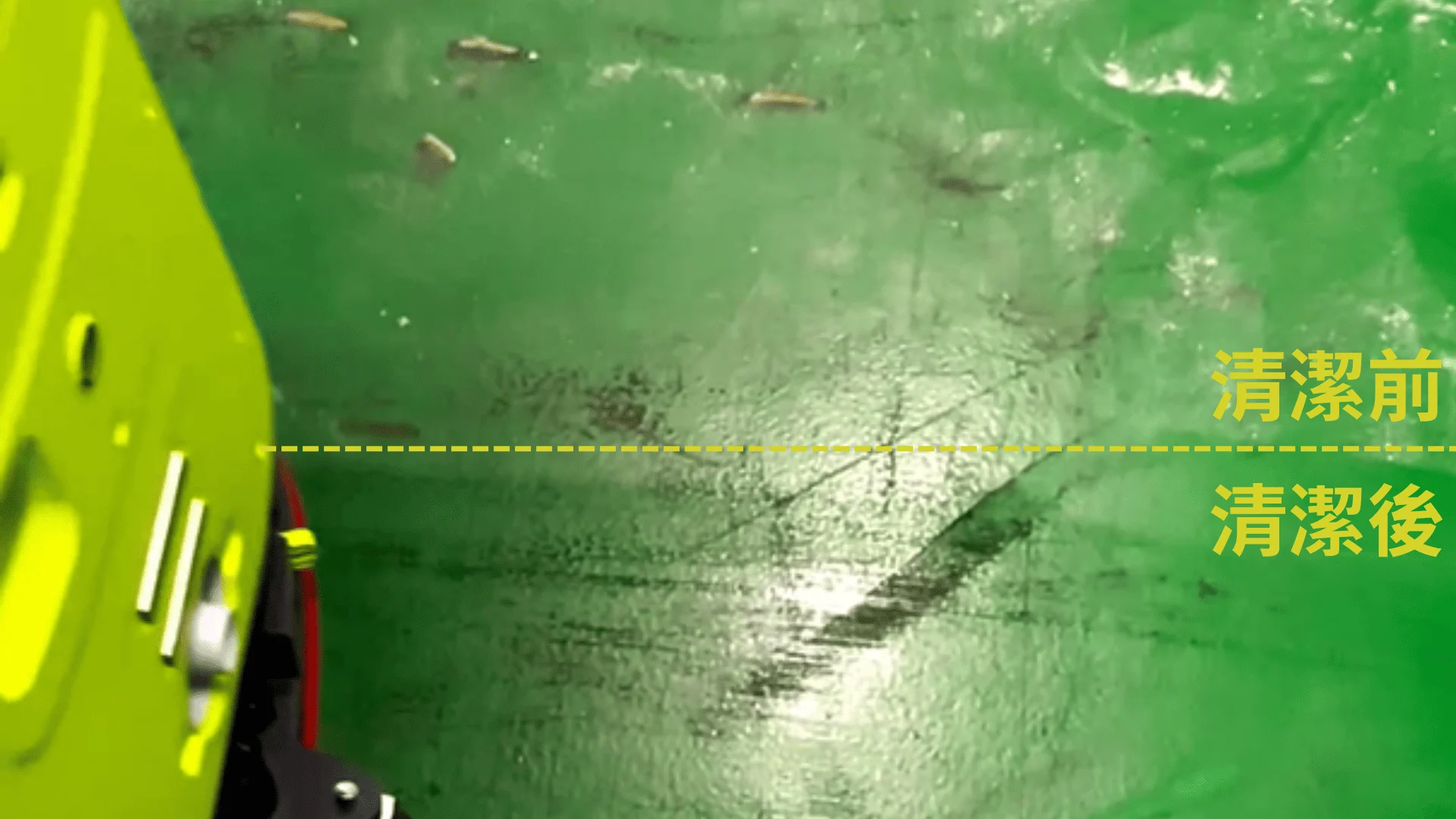

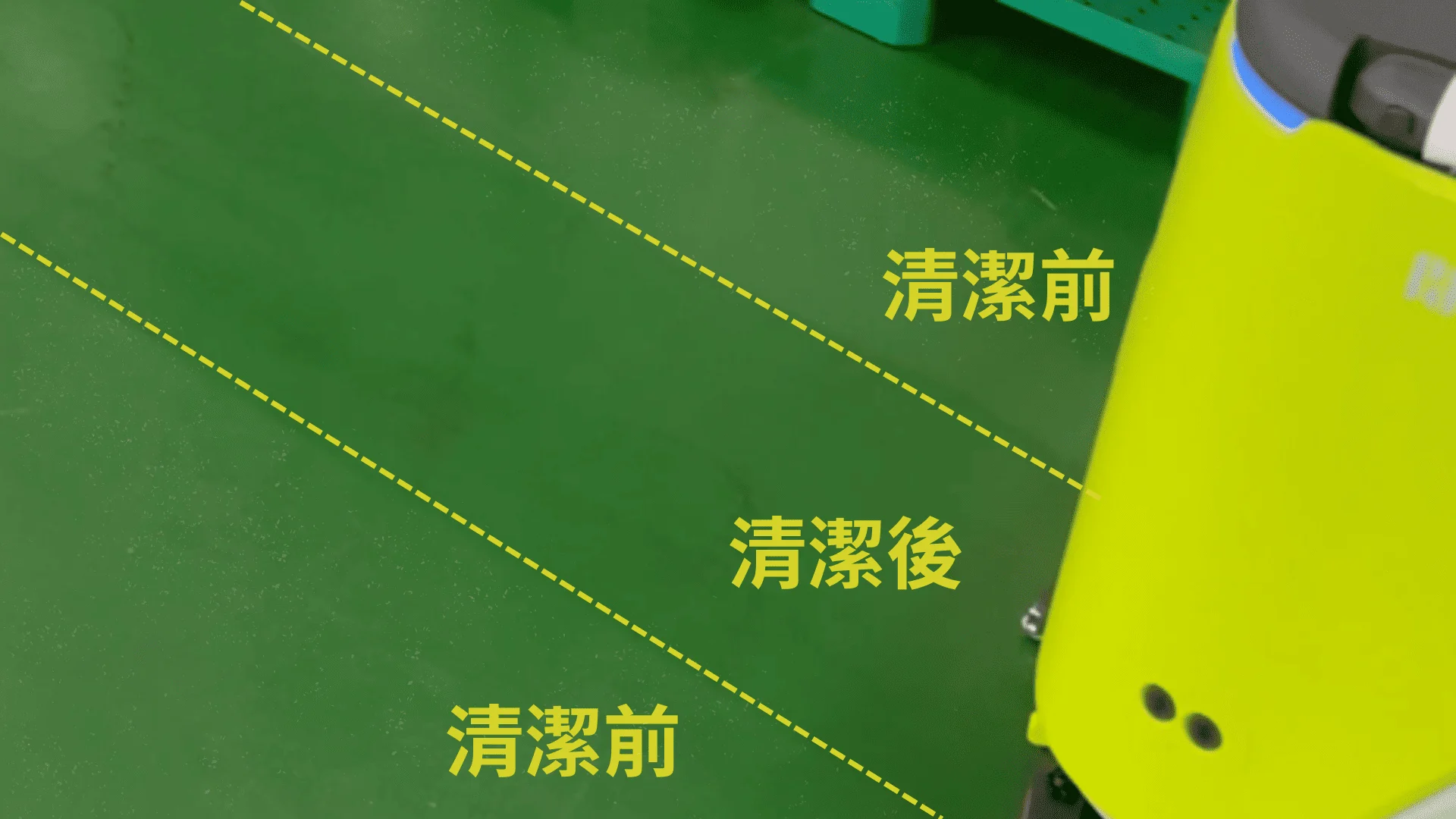

At See Box Corporation, after deploying the CC1 cleaning robot, wheel marks and footprints in the shipping dock area disappeared completely. Employees no longer track dirt into the inner production zone, resulting in a noticeably cleaner and more organized working environment.

In plastic manufacturing facilities, long-term exposure to airborne plastic dust poses potential health risks for employees. Combined with the complexity of the work environment, these issues have long been major challenges for factory operators.

CC1 cleaning robot’s scrubbing mode helps prevent dust from becoming airborne, while its edge-cleaning capability ensures a truly zero-blind-spot cleaning experience. This not only reduces manpower requirements but also improves cleaning efficiency by 40%. The comparison below clearly shows the difference before and after CC1’s cleaning performance.

Aurotek Value-Added Services|Solving Multi-Floor Cleaning Challenges & Enhancing On-Site Security

Beyond cleaning difficulties, many factories also face the following issues:

- Multi-Floor Cleaning: Numerous production lines spread across different levels require frequent cross-floor cleaning.

- Nighttime Security Risks: Large factory areas with limited night staff create blind spots and raise safety concerns.

Facing these challenges, the client partnered with Aurotek to implement customized value-added services.

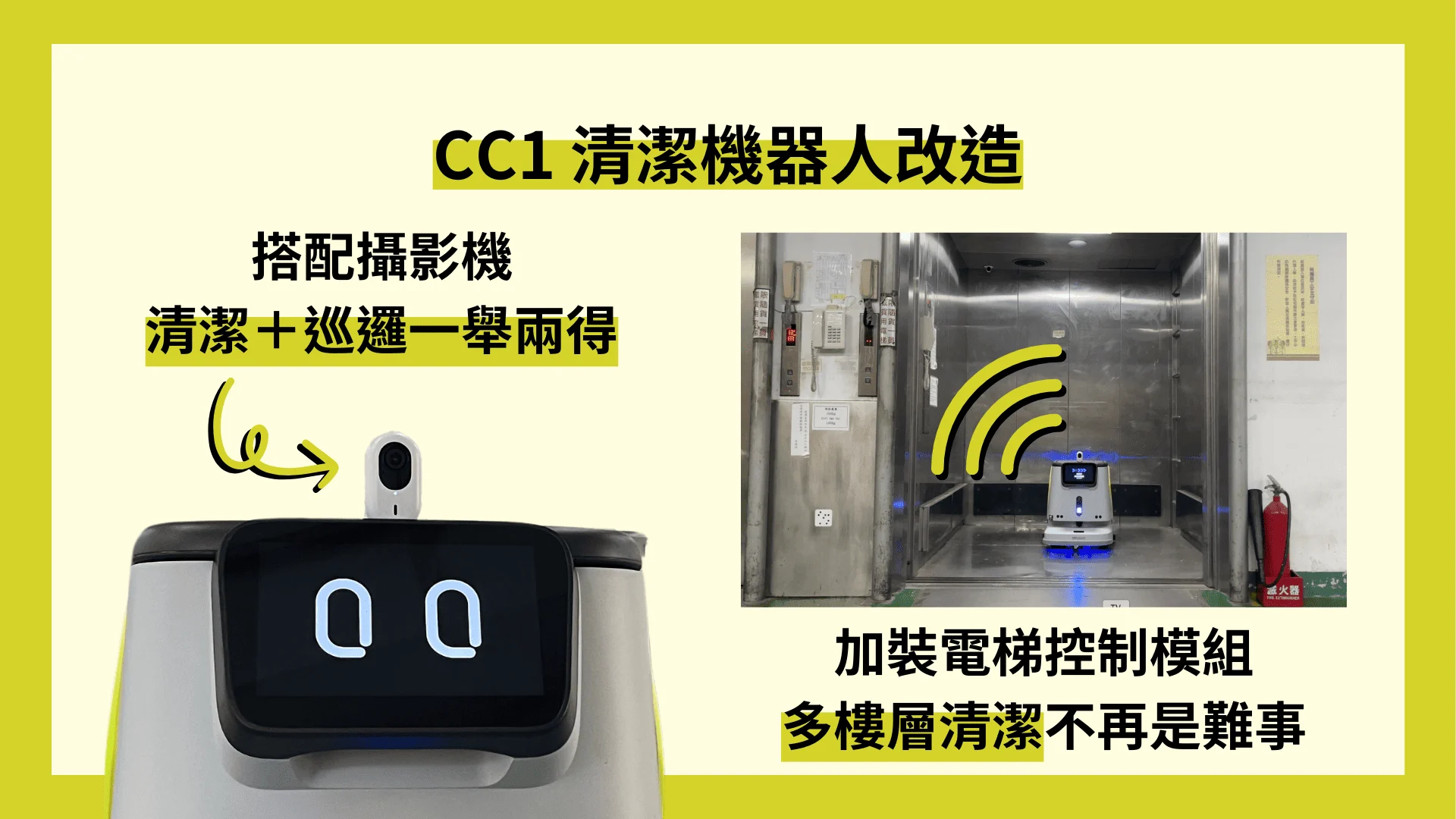

Install the “Elevator Control Module”: Meet multi-floor cleaning needs and further expand the cleaning coverage.

The elevator control module enables cleaning beyond a single floor, expanding the cleaning area and enhancing the robot’s flexibility and applicability across different environments.

Cleaning robots equipped with “cameras”: allowing mobile monitoring of cleaning status and enhancing site security during nighttime cleaning.

In response to See Box Corporation’s needs, Aurotek assisted in adding cameras to the cleaning robots. During the cleaning process, the situation within the site can be monitored, and the robot simultaneously provides cleaning and patrol functions, improving factory area safety while also reducing the need for patrol personnel.

Watch the video to learn more about See Box Corporation’s real-world application!